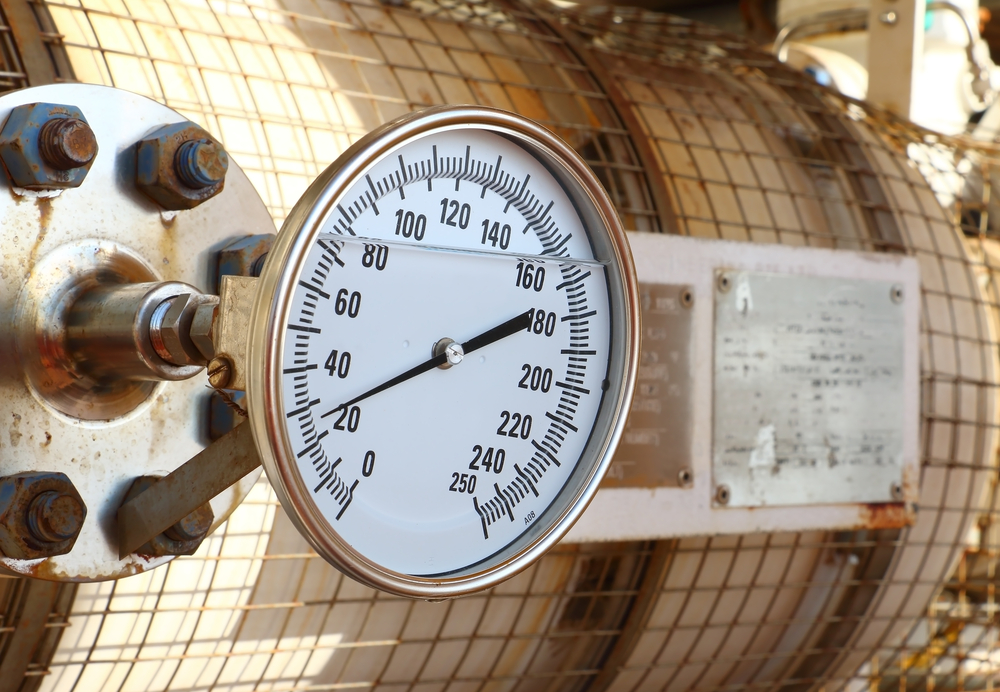

Pressure vessels are essential containers used in diverse industries to store liquids or gases under varying pressures. They play a critical role in maintaining safety and operational efficiency. Understanding the different types of pressure vessels is crucial for selecting the right one for specific applications.

From distillation columns in the chemical industry to boilers in power plants and heat exchangers in HVAC systems, each type serves a unique purpose. Proper selection and maintenance of pressure vessels are vital to prevent accidents and ensure optimal performance in industrial settings.

1. What Are Pressure Vessels?

Pressure vessels are specialised containers used to store or transport substances at high pressures. They find applications across diverse industries such as oil and gas, chemical processing, food and beverage, pharmaceutical, and aerospace. Selecting the appropriate pressure vessel for a particular application is crucial for maintaining operational safety and efficiency.

Factors such as the type of substance being stored, the required pressure and temperature conditions, and regulatory compliance must be considered. Proper selection and maintenance of pressure vessels are essential to prevent accidents and ensure optimal performance in industrial operations.

2. Types of Pressure Vessels

Distillation Columns

Distillation columns are crucial in the chemical industry for separating components in a liquid mixture. They work by heating the mixture to create vapour and then cooling the vapour to create a liquid. Distillation columns are used in processes such as refining crude oil and producing chemicals.

Boilers

Boilers are essential in generating steam for heating, power generation, or other industrial processes. They are widely used in power plants and various industrial settings. Boilers are designed to withstand high pressures and temperatures to ensure the efficient generation of steam.

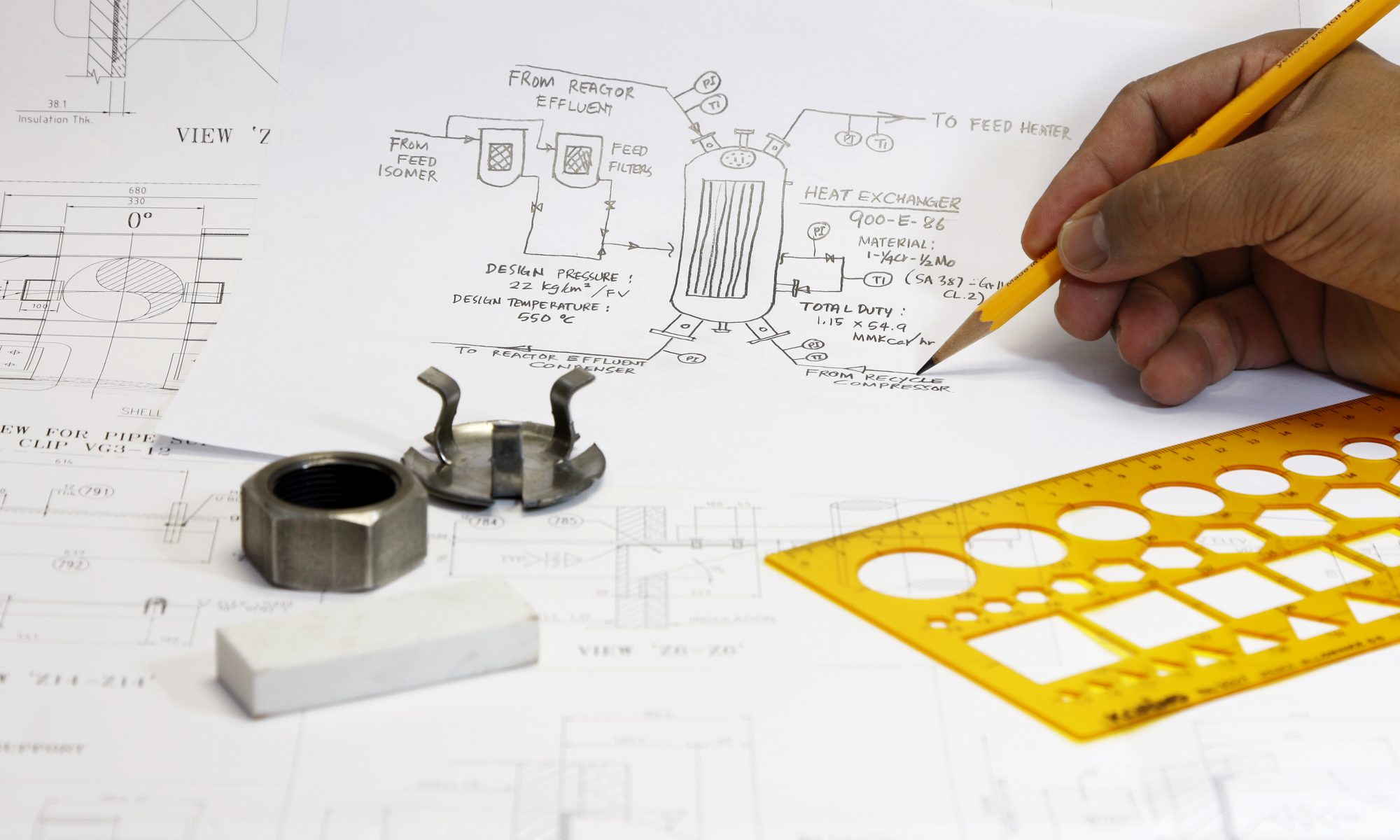

Heat Exchangers

Heat exchangers play a vital role in controlling temperatures and facilitating heat exchange in various industrial processes. They work by transferring heat between two or more fluids without mixing them. Heat exchangers are used in HVAC systems, refrigeration units, and chemical processing plants.

Reactors

Reactors are used to contain chemical reactions in industries such as pharmaceuticals and petrochemicals. They are designed to withstand high pressures and temperatures and provide precise control over reactions. Reactors are crucial for producing drugs, chemicals, and other products.

Storage Tanks

Storage tanks are used to store liquids or gases at different pressures and temperatures. They are widely used in industries such as oil and gas, chemical processing, and food and beverage. Storage tanks come in various sizes and designs to meet the specific storage requirements of different substances.

3. Applications Across Industries

Oil and Gas

Pressure vessels are integral in the oil and gas industry for storing and transporting crude oil, natural gas, and various petroleum products. They are used in exploration, production, and refining processes to ensure the safe handling and storage of hydrocarbons.

Chemical Processing

In the chemical industry, pressure vessels are used in various processes, including chemical reactions, distillation, and storage of chemicals. They are designed to withstand corrosive substances and high temperatures to ensure the efficient production of chemicals.

Food and Beverage

Pressure vessels play a crucial role in the food and beverage industry for processes such as pasteurisation, sterilisation, and fermentation. They are used to ensure the safety and quality of food and beverage products by controlling temperature and pressure.

Pharmaceutical

In the pharmaceutical industry, pressure vessels are used in the production of drugs, vaccines, and other medical products. They are designed to meet strict regulatory requirements and ensure the safe production of pharmaceutical products.

Aerospace

Pressure vessels are used in the aerospace industry for storing fuel, gases, and other fluids in aircraft and spacecraft. They are designed to withstand high pressures and temperatures experienced during flight and ensure the safety and reliability of aerospace vehicles.

4. Considerations for Choosing a Pressure Vessel

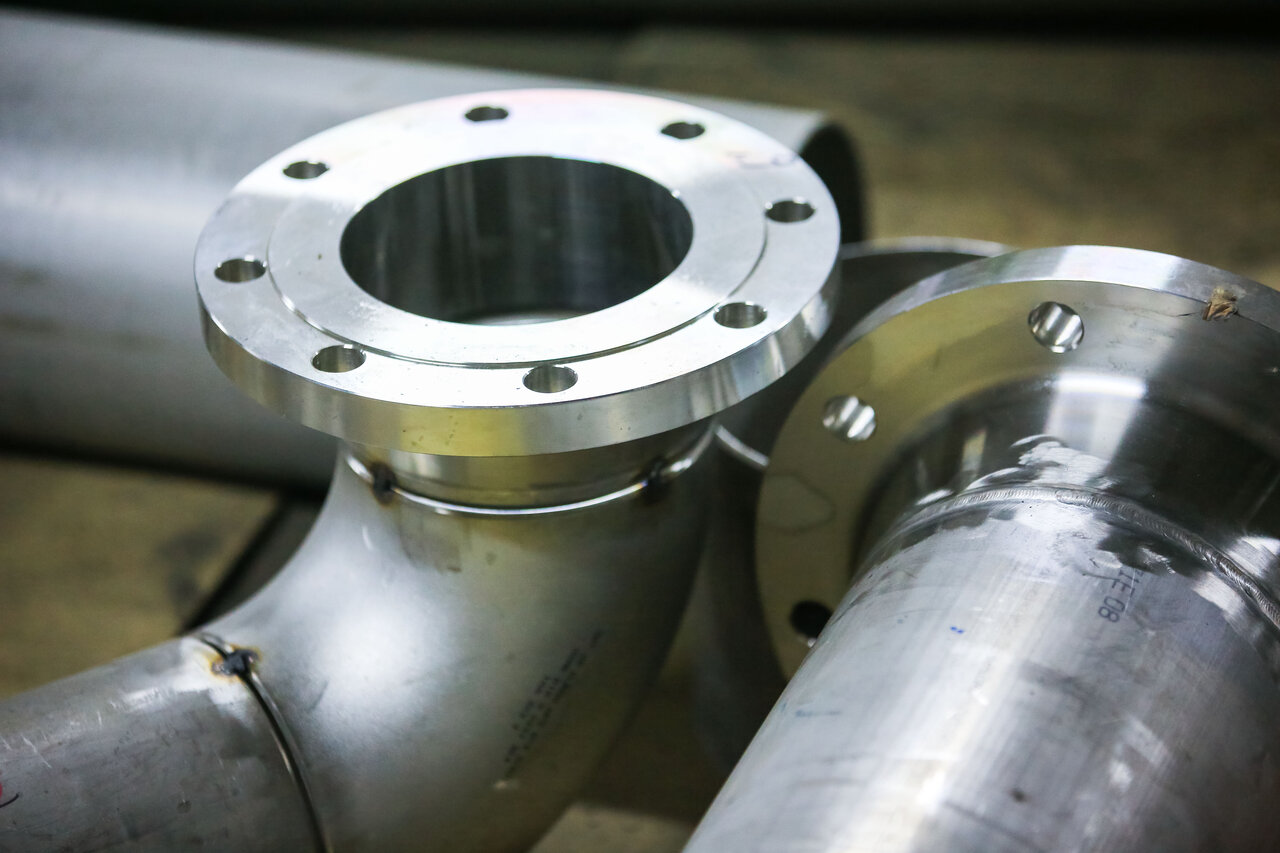

When selecting a pressure vessel, numerous factors must be taken into account to ensure its suitability for the intended application. Operating conditions such as pressure and temperature are critical considerations, as they dictate the vessel’s design specifications. The material used in the vessel’s construction must be compatible with the substances it will contain to prevent corrosion or contamination.

Additionally, regulatory compliance is paramount to ensure that the vessel meets all relevant standards and regulations for safety and environmental protection. Choosing the right pressure vessel is crucial for maintaining operational efficiency and preventing potential hazards. Therefore, careful consideration of these factors is essential to ensure that the selected vessel meets the specific requirements of the application and complies with all relevant regulations.

Final Thoughts

Understanding the different types of pressure vessels and their applications is crucial for ensuring safety and efficiency in industrial processes. By selecting the right pressure vessel for a specific application, industries can optimise their processes and enhance overall productivity. Pressure vessels are essential components in various industries, and their proper selection and maintenance are critical for ensuring the safe and efficient operation of industrial processes.

Choose Sherwood Engineering For Pressure Vessel Design

With over 40 years of experience in engineering design services, Sherwood Design & Engineering is committed to delivering excellence in pressure vessel design, manufacturing, and support services. Our team of qualified engineers, designers, and consultants are dedicated to meeting the unique needs of various industries, ensuring compliance with regulations, and providing innovative solutions that enhance safety and performance.

Give us a call at (02) 9437 3566 or leave an enquiry if you would like to learn more about our pressure vessel engineering design and support services.